Waterjet Cutting In Georgia

Industrial work and production has been on the rise in Georgia. In the second quarter of 2018, industrial production in Georgia increased 16.2 percent; that is 13.5 percent increase from the previous period.

Industrial work includes industries like mining & quarrying, electricity, gas, steam & air conditioning supply, water supply, waste management, entertainment, and more. These industries, and many others, rely on waterjet cutting for essential equipment to get their jobs done.

Other industries like pharmaceutical, petroleum, automotive, and aerospace, all rely on waterjet cutting to provide them a means of creating essential parts to do and complete their functions.

You likely see results of waterjet cutting work every day, you just don’t recognize it. Many businesses use waterjet cutting to cut metal signs for their companies, and many avenues of entertainment rely on waterjet cutting to create important parts and designs for their sets.

With how important and helpful waterjet cutting is to these industries, and many more, it’s no wonder waterjet cutting is becoming one of my the most popular ways to cut materials.

Cutting Experts are leading the industry in precision CNC waterjet cutting, CNC routing, and custom fabrication. We work with you through every step of the process to ensure complete satisfaction and exact desired results.

The Basics

If you’re new to material cutting or just have never heard of waterjet cutting, here are the basics of what you need to know.

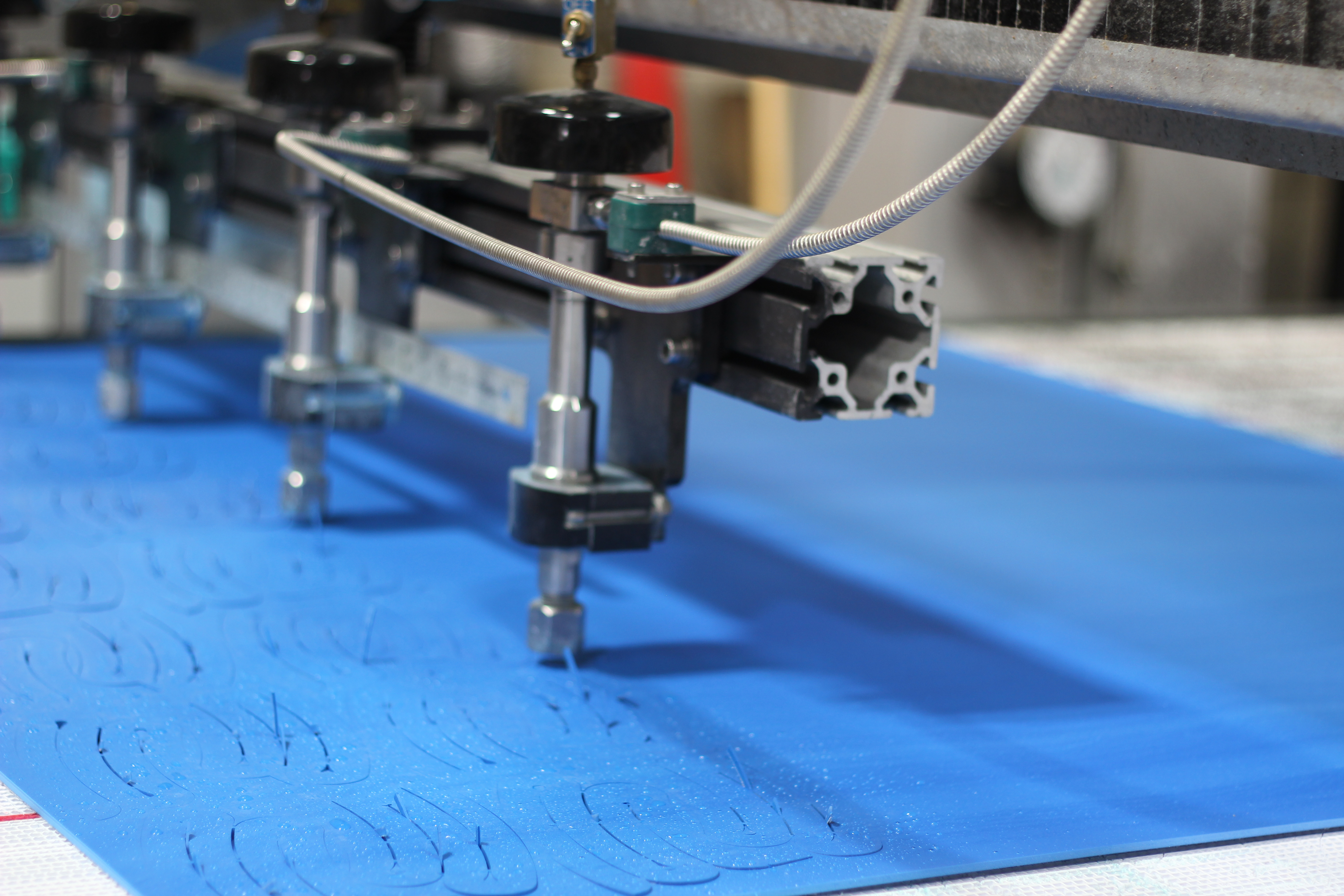

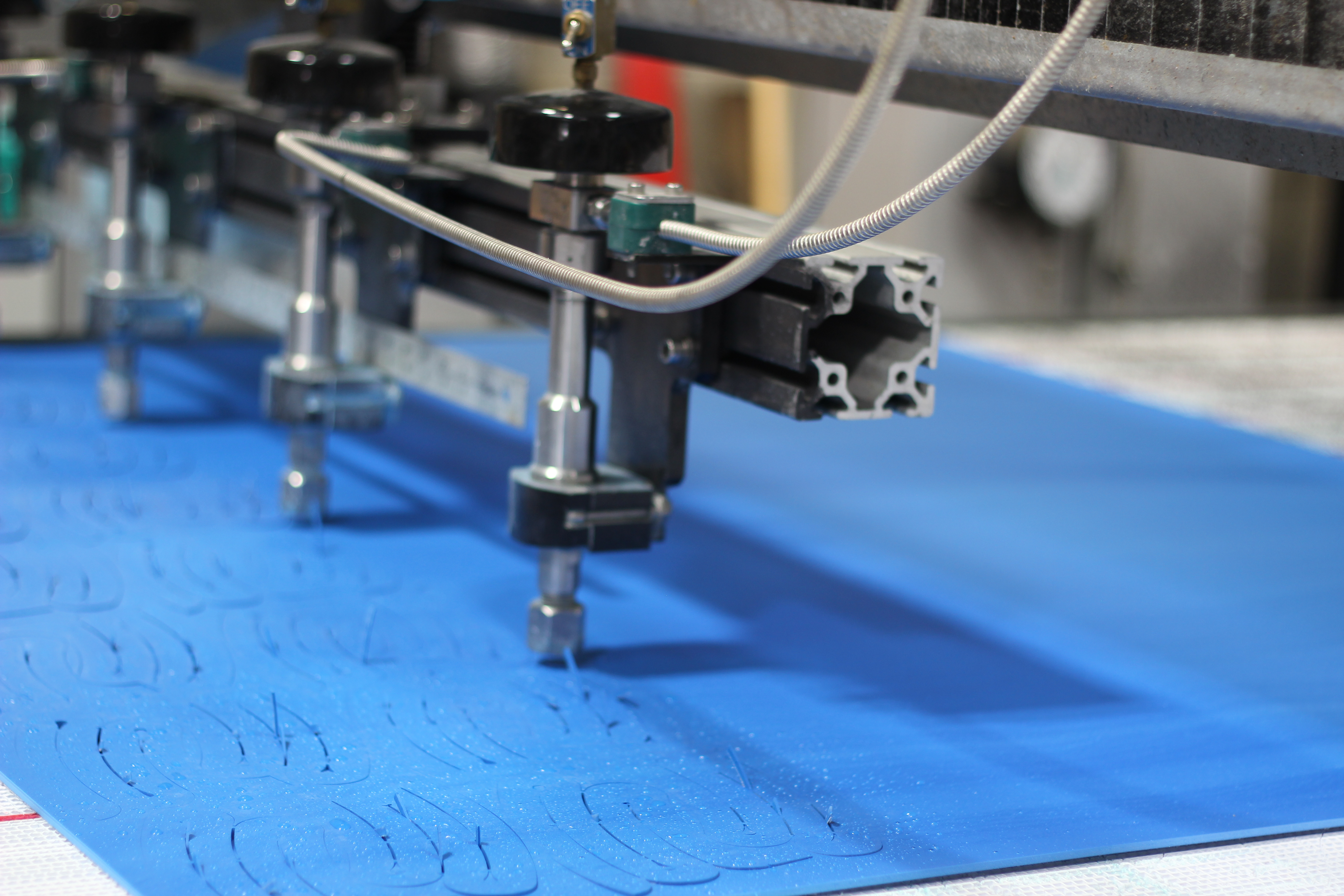

Waterjet cutting is done using a high pressure stream of water to cut materials.

There are two kinds of waterjet cutting, pure and abrasive.

Pure waterjet cutting is used on thinner or softer materials like foil, cardboard, rubber, fabric, and wood. It the original, and cleanest form, of waterjet cutting. However, waterjet cutting was taken up a notch by adding the use of an abrasive material, thus creating abrasive waterjet cutting.

Abrasive waterjet cutting utilizes abrasive particles, such as garnet, to give the high pressure stream of water the extra edge to be able to cut virtually any material. The water-abrasive mixture comes out of the cutting head at a speed four times faster than the speed of sound. This allows the abrasive waterjet to cut through thicker materials than most other cutting methods.

The Benefits

Other than what you have already read about waterjets, there are many more benefits.

Here are a few of the benefits waterjets offer:

Cuts virtually any material

From foam to metal, waterjets can cut virtually any material of any thickness. Diamonds and tempered glass are two materials that waterjets cannot cut. The most popularly cut materials by waterjets are metals because waterjets can create intricate shapes precisely, efficiently, and economically.

Extremely accurate and precise

Waterjets can cut materials of any thickness up to .001 of an inch. That is on par with laser and EDM cutting techniques and finer than plasma cutting. Waterjet cutting can be combined and controlled with computer numerical control (CNC). This is a computer software that will control the waterjet to cut exactly to the dimensions that are entered via data inputted. This results in an extremely accurate finished product that is easily reproducible.

No secondary finishing

One session with a waterjet will get the exact results desired. Many other material cutting techniques will have burrs or other inconsistencies that need to be corrected after cutting. Waterjet cutting creates a satin-smooth finished edge with minimal kerf.

No heat-affected zones

Unlike most other materials, waterjet cutting is a cold-cutting process. This means that it does not use heat in the process of cutting the material, so there will be no areas of the final product that are damaged, distorted, or discolored by heat.

Environmentally friendly

: Waterjets are the most environmentally friendly material cutting technique. It is the only method that does not produce toxic fumes, deposits, or carbon build up. The majority of waste from waterjets is suitable for landfills or can be recycled.

When it comes to finding a contractor for your cutting projects in Georgia you have many options. Not all of those options can offer you what Cutting Experts offers.

At Cutting Experts we work with experts who average over 25 years of experience in the field. Unlike other cutting companies, we work with any material, and have the equipment and knowledge to work on a broad range of projects. We will work alongside you, and guide you through every step of our process.

We have been proudly and happily providing waterjet cutting and CNC routing needs in Georgia since 1977. We have built a reputation as one of the most trusted sources for material cutting needs and continue to provide and adapt to our clients needs.

To find out more about how Cutting Experts can help you, request a quote for more information, or call us at 1-800-530-9051.